Former Spin-outs Denmark project NitroVolt aims to radically transform ammonia production in the coming years with their groundbreaking invention. But having a great invention isn’t enough — there also needs to be a market for it.

It is not easy to overlook NitroVolt‘s new lab.

Located in a big 3000 m2 factory hall at Alfa Laval Innovation House in Søborg, Copenhagen, the lab consists of three green containers combined into one with an orange door – matching the colors of the company’s logo.

‘We started building it in March 2024, and then we moved in on July 1st,’ says Suzanne Zamany Andersen, co-founder and CEO at NitroVolt.

‘Everyone rents an empty space in the factory hall, and then each startup has to build their own facilities. We got inspiration from some of the other startups here for the chemistry lab,’ she continues as she gives the grand tour in the hall, where more startups are located.

Inside the lab, the two engineers Aniket Mule and Olivia Westhead are working on NitroVolts technology. There is a slight problem with adjusting to the new environment, away from the labs at the Technical University of Denmark, where the project has its roots.

‘In here it is colder in winter, and the chemistry does not like it to be cold. So, we are now looking to tweak the chemistry to fit better with Danish winter,’ Suzanne explains.

Progress and Funding

The container and new lab are not the only thing, that is hard to overlook.

So is the progress of the climate technology spinout, that since leaving the Spin-outs Denmark program in 2023, has gone from 4 to 13 employees.

But that’s not all for NitroVolt; They are aiming to revolutionize worldwide ammonia production in the coming years with their system called the Nitrolyzer.

In November 2024, the spinout secured €3.5 million in a Seed funding round that included BackingMinds, EIFO, EQT Foundation, Satgana, DivisionM, and Breakthrough Energy Foundation.

This was not the first time that Breakthrough Energy Foundation showed interest in NitroVolt. Already in the late summer of 2023, they secured a fellowship grant from the Bill Gates organization, which gave them access to a grant and lots of courses, networking opportunities, and support.

‘It was fantastic. We had online sessions sometimes as much as twice a week, going over everything from techno economic analysis, life cycle assessment, how to build a business, founder burnout, how to dress when you’re doing interviews, etc. – it was so hands-on and offered so much tangible support,’ says Suzanne.

The Nitrolyzer

The grant money from Breakthrough Energy Fellowship was spend on building the new NitroLabs, where they can continue the tireless work with their product.

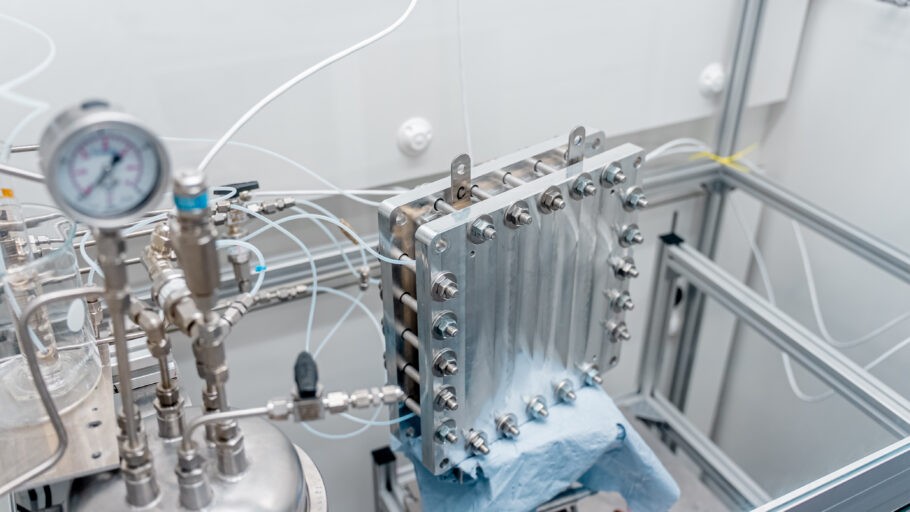

‘This system will make around 1 kilogram of ammonia per day,’ Suzanne explains, while pointing to the newest version of the Nitrolyzer stack.

The Nitrolyzer is a patent pending lithium-mediated ammonia synthesis reactor, which is part of a larger system that will only require air, water, and green electricity to synthesize sustainable ammonia directly at the point-of use. This means that the individual farmer will gain control over their own nitrogen-based fertilizer supply.

This is not only good for the farmer, but also great news for the environment, because when ammonia is produced right where it is needed, it will eliminate fossil fuels completely from the ammonia equation.

‘The farmer needs on average 100 to 200 kilos per day depending on the farm size and crops, so we are working on scaling it up,’ she says.

‘We know nothing’

Suzanne had no idea, that the potential was this big, going into her PhD interview at the Technical University of Denmark back in 2017. She didn’t even know that much about ammonia production.

‘I wanted to do my PhD on something that mattered and could have impact,’ says Suzanne.

At the interview, she was presented with different projects, and one of them caught her attention.

‘They had an ammonia project, that they had been working on for 15 years, but it didn’t work. They explained to me how important ammonia is to our modern society, and that without it, half of us wouldn’t be alive. But the current process emits a lot of CO2 – roughly equivalent to the entire aviation industry – and is therefore not good for the environment. I was immediately sold on the scale of the problem, and I like a good challenge,’ she recalls.

When she finished her PhD, she had the first patent in place, and more patents followed. At this point, Suzanne realized that this was more than a research project.

She asked Mattia Saccoccio, NitroVolt’s co-founder, if he would like to do a startup with her.

‘He very hesitantly said yes, but also that if we did this, we should go talk to customers. He was the first one, that made me realize: we know nothing about the use of ammonia,’ Suzanne says.

70 customer discovery interviews

The importance of knowing the customers is something that not all researchers realize when they transition into entrepreneurship.

For Suzanne and Mattia it meant that they had to start visiting farms and farmers. This groundwork is one of the keystones to why investors want to be part of NitroVolt’s journey: The spinout knows their customers.

The first two conversations with growers gave them crucial learning on farming and taught them that although their product was made of only water, air and green electricity, it was not considered organic, because the generated ammonia still undergoes a chemical process. Therefore, it could not be used as organic fertilizer.

But on the third farm, something clicked.

‘Here was a customer, that was interested. He asked us when we could sell him the product,’ says Suzanne.

Both Mattia and Suzanne learned even more about their potential customers, when they got into Stanford Climate Ventures – a project-based quarterly course that practices the creation of transformational climate ventures and innovation models.

‘There we had to do 70 customer discovery interviews in 70 days. It really surprised me how many people were willing to put aside 30 minutes of their time to talk to us. That really refined us. Mattia then spent time with an expert building a very solid TEA, that has impressed the investors we have talked to since ,’ says Suzanne.

TEA stands for techno-economic analysis – a tool used to evaluate the cost and price of a startup’s product when built at scale. This can help startups get a tangible price for their product that they can validate with future customers.

‘You don’t know who your customer is. You don’t know what their pain points are. You don’t know whether they’re interested or not. Are you solving a real problem for a customer? Or is it just an imagination you have that this is a problem? You need to figure out where the best market is for your product, and the only way to do that is to talk to people’ she says.

Homework and commitment

Suzanne joined the Spin-outs Denmark program in 2022 as part of the very first cohort. Especially the grant was a gamechanger.

Now her salary was covered for a year, and that freed up other resources which enabled NitroVolt to hire another person full time.

The Masterclasses gave her a lot of challenges to ask questions and get help with pressing problems, but she would have liked it if there had been more forced contact with potential customers.

‘Researchers will spend time in the lab building the best product in the world, having no idea if there is anyone on the other end willing to pay for it. I think part of the Spin-outs Denmark program should be that we have talk to 100 people over 1 year in the field we intend to operate in with our product. It’s not a big ask. It’s about one person every third day of the program,’ Suzanne ponders.

She would also have welcomed homework between the Masterclasses – to show the commitment to the program.

Impact as a driver

Suzanne is already committed. She is committed to changing the way the world’s food production is set up today.

‘The way you produce ammonia today is in these huge multi-billion-euro facilities that are primarily located in Russia, China, the US, etc. And they use fossil fuels as the input to generate ammonia, leading to around 1.5% of the world’s CO2 emissions. Furthermore, because it’s a central production facility, you have logistics and distribution costs on top of production costs, as well as more CO2 emissions to get it out to these typically very rural areas that farmers are located in. There are many regions in the world that simply don’t have access to ammonia due to lacking infrastructure and too expensive distribution costs,’ she says.

That means, for example, that in many landlocked countries in Africa, the price of ammonia is three times what a farmer in Denmark would pay, and because of that, they just don’t have synthetic nitrogen fertilizer in these difficult to reach regions.

‘So that’s where we want to go. Not only because our product is green with no direct CO2 emissions and no emissions from transportation either because it’s on site, but also because we can have the biggest societal impact by going to these remote regions and enabling food production. That is what drives me as a person,’ says Suzanne.

And the first steps of these goals are getting the Nitrolyzer to market in the next five years.

‘We want to build our NitroFacility in 2027, which will then enable us to build the first full scale systems in 2027 and 2028,’ she says.

And the dream for where NitroVolt will be in ten years, is also clear.

‘We will reduce a lot of greenhouse gas emissions, and every single ammonia user in the world will have heard about us. That’s our goal. And that’s why we are already talking to a global audience,’ Suzanne concludes.

Spin-outs Denmark is a unique program that invests in researchers who create more impact by starting research-based companies.